NEXUS PROSTHETICS

The Advanced Prosthetic Option

Two-piece design, titanium framework, monolithic overlay.

Innovative bar profile distributes occlusal forces.

Offers overlay material options.

Over 7 years of proven patient outcomes.

HOW IT WORKS

TOOTH DESIGN ⮕ PRECISION MILLED BAR

Designed to validated tooth position. File split, bar milled.

Osteon Medical designs the Nexus bar profile to match the arch, following proven design parameters. A digital approval is sent before production. Once signed-off, the bar is milled, overlay file provided for milling in-lab including relevant models to 3D print and assist with finishing.

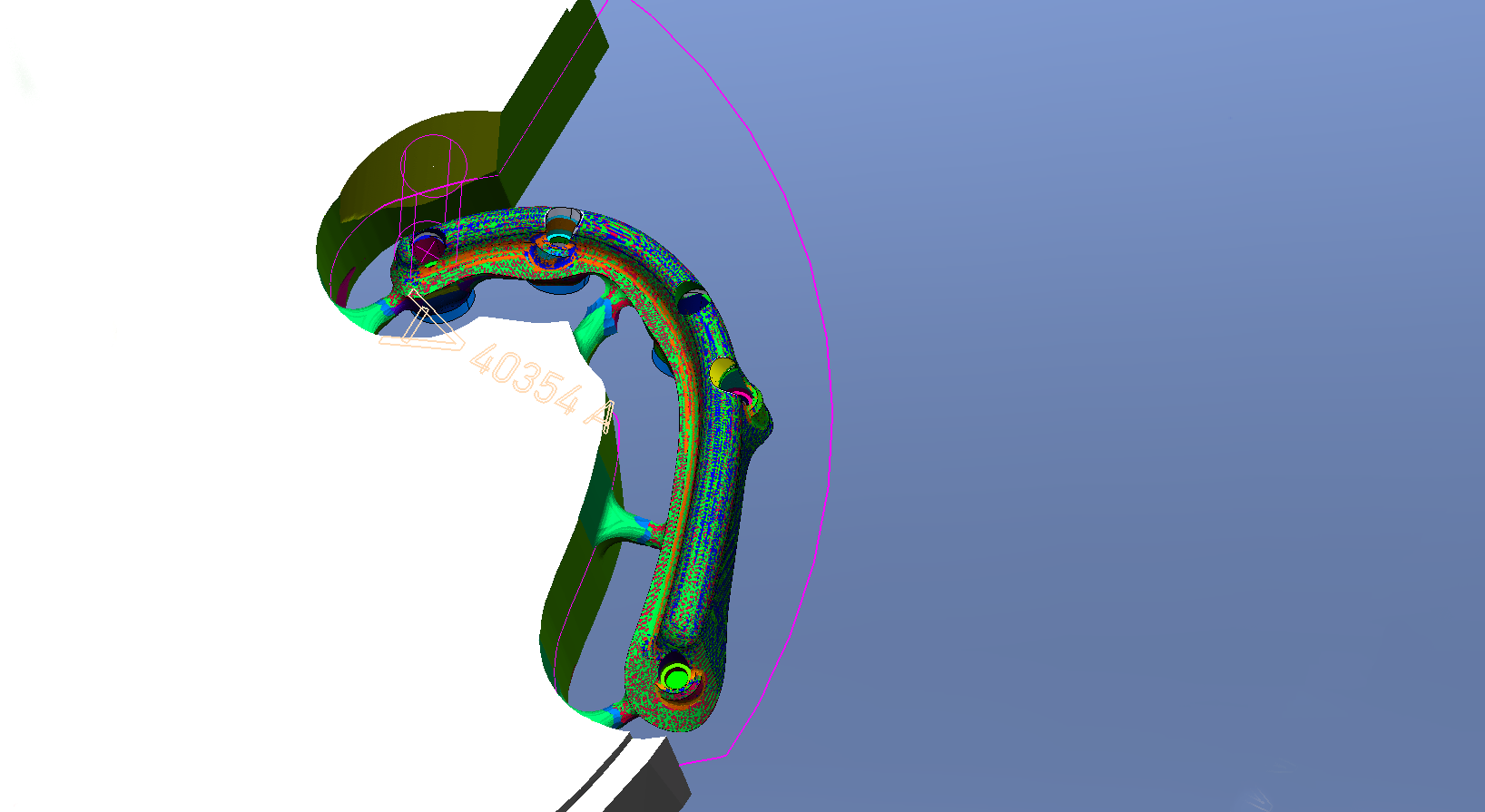

Precision Data, Precision Milling

Osteon has been milling advanced implant frameworks for 15 years.

Expert milling strategies have been pioneered for this application, making the titanium frameworks that come from Osteon unparalleled in their form and function.

SUPERIOR PROSTHETIC DESIGN

Developed and refined for over 7 years.

The fundamental concept of Nexus' final prosthetics is a monobloc-milled overlay and a titanium suprastucture.

Having matching male and female components, occlusal forces are distributed evenly across the prosthesis. Combined with a proprietary internal rail and a lingual ledge profile - this provides rigidity that transfers forces to the bar, not the teeth material.

Unmatched Strength

Nexus prosthetics are proven to be stronger and more durable than conventional prostheses.

*Nexus Hybrid Acrylic vs Conventional Acrylic Hybrid - The International Journal of Oral & Maxillofacial Implants, 01/2020